quantitative correction

quantitative correction

A correction to obtain the correct concentration values of the constituent elements in an unknown specimen using the characteristic X-rays generated by electron beam irradiation. The correction is applied to the first approximate concentration value, which is calculated using the intensity ratio (K ratio = CU/CStd) of the characteristic X-rays from the unknown specimen and the standard specimen (mass concentrations of the constituent elements are known).

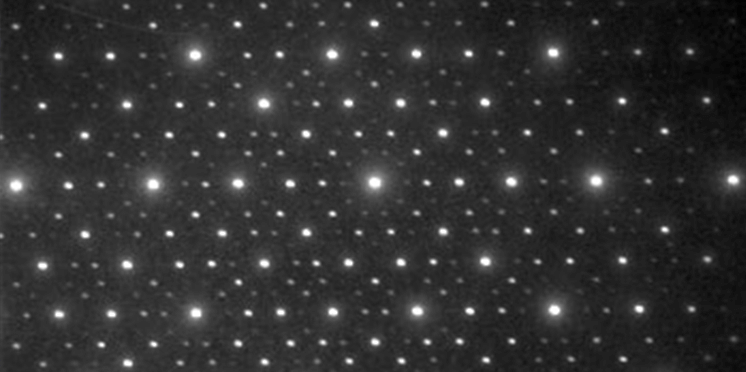

The constituent elements and their abundance ratio of the unknown specimen are different from those of the standard specimen. As a result, the measured K ratio is not equal to the concentration ratio of the unknown specimen to the standard specimen. Thus, corrections are needed to obtain the correct concentrations of the unknown specimen. The correction factor G is composed of the following three corrections: 1) Atomic number correction GZ due to the difference of characteristic X-ray generation efficiencies, 2) Absorption correction GA due to the difference of absorption of the characteristic X-rays when they run in the specimen and 3) Fluorescence correction GF due to the difference of fluorescence X-ray generation efficiencies (Fig. 1). Methods for calculating these correction factors include the ZAF correction method and the Phi-Rho-Z method (φ(ρz) method).

The workflow of the quantitative correction (in standard quantification) is shown in Fig. 2. To obtain the correction factor G, first, all the characteristic X-rays generated from the unknown specimen are measured and the constituent elements (N = A, B, C,…) of the specimen are identified. In the following, we explain how to obtain the mass concentrations of the elements in the unknown specimen with the corrections described above.

The first approximate concentration value CA0 of element A in the unknown specimen is calculated by multiplying the measured K-ratio KA = CAU /CStdA by the mass concentration CStdA of element A in the standard specimen. By the same procedure, the first approximate concentrations CB0, CC0… of elements B, C...in the unknown specimen are calculated. Then, the correction factor GN0 (N=A, B, C…) is calculated using the first approximate concentrations CN0 of all the constituent elements contained in the unknown specimen. The second approximate mass concentration CN1 is calculated by multiplying GN0 by the first approximate concentration CN0 (= CStdN x KN). Next, using the corrected mass concentration CN1, GN1 is obtained, and CN2 is calculated by multiplying CN0 by GN1. By repeating this procedure, when the calculated mass concentration CNi+1 becomes very close to the previous CNi, the value is taken as the true value.

There are two methods for determining the K ratio and CN0: (1) standard quantification, in which a standard specimen is prepared and the characteristic X-ray intensity is actually measured, and (2) standard-less quantification, in which a theoretical calculation or reference data prepared by the EDS manufacturer is used.

When the difference in the average atomic number of the constituent elements is large between the unknown specimen and the standard specimen, the correction amount becomes large because the difference of the characteristic X-ray generation efficiency and of the absorption in the specimen becomes large. In general, the effect of absorption correction is largest, followed by the atomic number correction and the fluorescence correction. In particular, when the accelerating voltage is high (e.g. 20 kV, 30 kV), the electron beam penetrates deeper into the specimen while generating the characteristic X-rays. Thus, the X-rays run a longer distance in the specimen, and then, the absorption correction becomes important. Fluorescence correction can often be neglected because the fluorescence effect is small except for the combinations of specific elements. For the detailed explanations of the absorption correction, atomic number correction and fluorescence correction, refer to the term “ZAF correction”.

Fig. 1 Three correction factors used for quantitative correction

A part of electrons incident into the specimen is scattered elastically and inelastically with the constituent atoms (elements) (①). Some electrons are backscattered and emitted outside the specimen as reflected electrons. The electrons penetrating into the specimen generate continuous X-rays and the characteristic X-rays of element A (②). The penetrating electrons also generate the characteristic X-rays of element B (③). In this inelastic scattering process, these electrons lose their energy. The difference in the characteristic X-ray generation efficiency between the unknown specimen and the standard specimen in such scattering process is corrected as the atomic number correction factor GZ.

A part of the generated characteristic X-rays is absorbed by the specimen. Since the magnitude of absorption for the characteristic X-rays depends on the constituent elements and their abundance, the difference between the unknown specimen and the standard specimen is corrected by the absorption correction factor GA (④).

In some cases, the characteristic X-rays of element A are excited by the characteristic X-rays of the other element B (③) or by continuous X-rays, and the X-rays of the same energy as the characteristic X-rays of element A (fluorescence X-rays) are generated (⑤). The difference in the fluorescence X-rays between the unknown specimen and the standard specimen is corrected by the fluorescence correction factor GF.

Fig. 2 Workflow of quantitative correction of constituent-elements concentrations in an unknown specimen.

Related Term(s)

Term(s) with "quantitative correction" in the description

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.