focused ion-beam milling, FIB

focused ion-beam milling

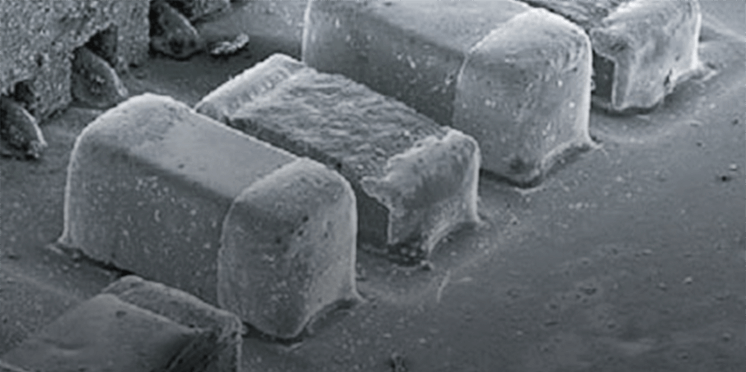

"Focused Ion Beam (FIB) milling" is a technique of a TEM specimen preparation to mill a bulk specimen with focused gallium (Ga) ions. The target region of the bulk specimen can be selectively thinned down to a desired shape while monitoring and controlling by SEM observation of the milling region. This technique is particularly indispensible for failure analysis of semiconductor devices.

The FIB milling procedure is as follows: First, the surface of the target region is coated with a platinum- or carbon-protective film in the FIB system to avoid the milling of the target region (Fig. (a)). Next, the target region is milled with a Ga ion beam of a high accelerating voltage of about 30 kV to prepare a section of a thickness of a few μm or less (Fig. (b)). Then, the prepared section is picked up from the bulk specimen and fixed onto a TEM specimen grid (Fig. (c)). Finally, the fixed specimen is milled with a Ga ion beam of a low accelerating voltage of about 5 kV (for decreasing damages to the specimen) to create a thin section of a thickness of 10 to 100 nm (Fig. (d)). If the damaged layers due to the irradiation of Ga ions remain, the layers are removed by another milling with a Ga ion beam of a lower accelerating voltage (about 3 kV or less) or with an argon (Ar) ion beam.

Fig. (a) Protection layer is formed on the target region by coating of carbon or platinum. (b) Surroundings of the target region are roughly milled with Ga ion beam to prepare a section (thickness: a few μm or less). (c) A section is fixed onto a TEM grid. (d) Thin section (thickness: 10 to 100 nm) is created from the target region by fine milling. (e) The thinned section prepared by FIB is subjected to TEM observation.

Related Term(s)

Term(s) with "focused ion-beam milling" in the description

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.