電解研磨

電解研磨

electrolytic polishing

[目次:試料等(試料および試料作製)]

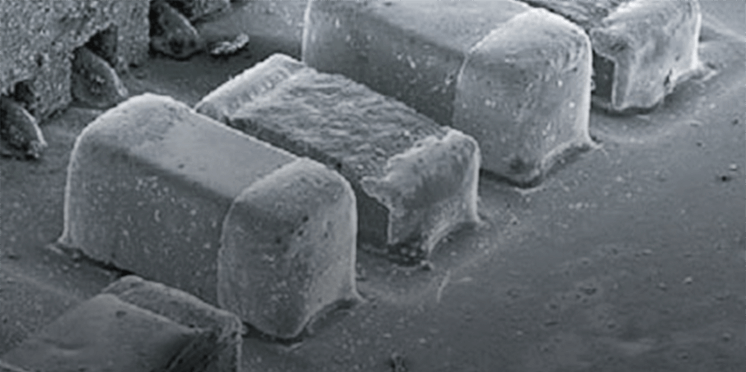

金属、合金の薄膜試料作製に使われる方法。適当な電解質溶液中に浸し、試料を陽極、白金板やステンレス鋼を陰極とし、直流電流を流すことにより試料表面から原子を溶出させ、試料表面を平滑に保ちながら薄膜化する。機械的なひずみを与えずに試料作製ができるのが利点。

"Electrolytic polishing" is a technique used for preparing a thin film on metal, alloy, etc. In this technique, a specimen (acting as an anode) and a platinum (Pt) plate or a stainless-steel (acting as a cathode) are immersed in a suitable electrolyte solvent. Then, an electrostatic potential is applied between these electrodes to elute the atoms of the specimen surface, and finally the specimen surface is thinned with its surface kept smooth. The advantage of electrolytic polishing is that a thinned specimen can be prepared with no mechanical stress.

関連用語から探す

説明に「電解研磨」が含まれている用語