波長分散X線分光法

波長分散X線分光法

wavelength-dispersive X-ray spectroscopy, WDS, WDX

[目次:分析]

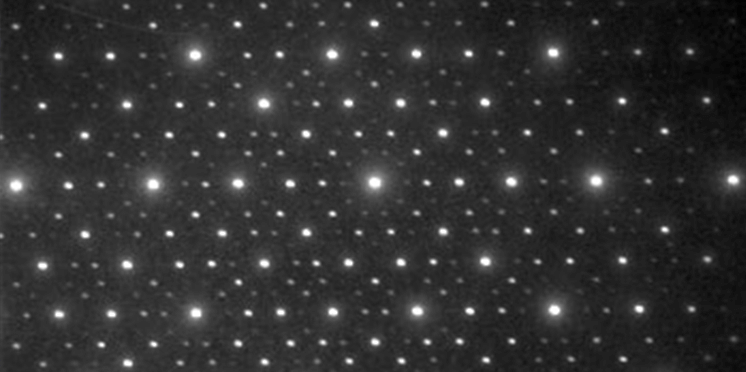

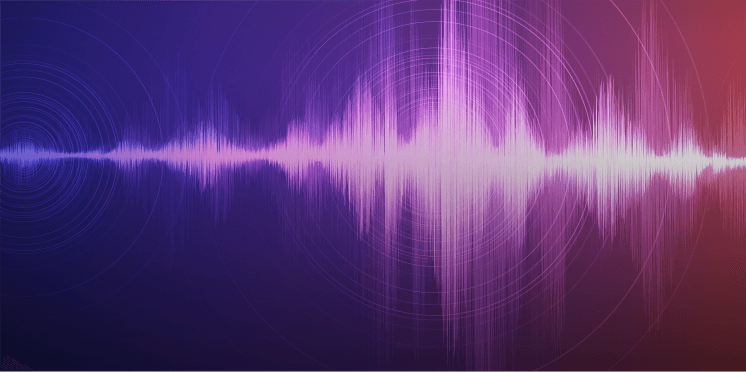

試料から放出された特性X線を波長分散型X線分光器によって分光し、得られたX線スペクトルの波長から試料の元素を特定(定性分析)すること、および定性分析によって分かった試料構成元素の濃度をスペクトルの強度から算出する(定量分析)手法。Be~Uまでの元素を検出できる。エネルギー分解能は約20 eVで、EDSよりも1桁高い。このため、エネルギー値が近い特性X線を確実に分離してそれぞれの元素を同定することができる。また、検出限界(微量元素の検出能力)は、スペクトルのS/Nが良いため、EDSに比べて約2桁高く、100 ppm以下微量元素(特に微量軽元素(B~F))の検出が可能である。WDSによる定量分析で得られる定量値の精度は高く、湿式化学分析による定量値に近い。分析領域の大きさは、入射電子が試料内で拡散するため、水平方向、深さ方向ともに、EDSと同様に、数100 nm~数 μm程度である。

エネルギー分解能が高いため、構成元素のエネルギー値が近接している試料や、L線が極めて近いエネルギー領域に集中している希土類を多く含む試料では、EDSでなく、WDSでないと構成元素の分離・同定(定性分析)ができない。

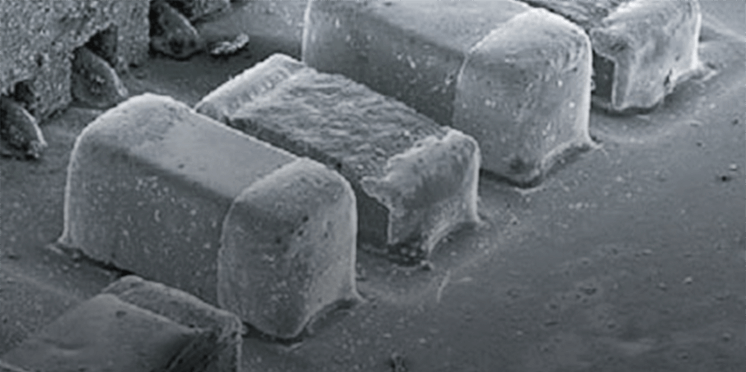

ただし、波長分散型X線分光では、装置がEDSに比べて大型で複雑である。WDSは分光結晶に入射したX線のうちブラッグの回折条件を満たしたX線のみを分光して検出するため、そのX線検出効率はEDSの1/100程度である。そのため、WDSではS/Nの高いスペクトルを得るために大きなプローブ電流(数100 nA以上)が必要で、熱に弱い試料では電子線によるダメージを受ける場合がある。また、異なる元素の特性X線を検出する場合、分光結晶とX線検出器をローランド円と呼ばれる円周に沿って機械的に移動させて、一つ一つの特性X線を時系列で検出するため、分光は波長ごとに行うので、EDSのように異なる元素を同時に分析することができず測定時間は長くなる。さらに、WDSでは試料表面の分析領域に10 μm近いあるいはそれ以上の凹凸があると、分析点がローランド円から外れて、検出点での特性X線の収束性が悪くなり、X線強度が低下する。そのため、試料の表面は機械研磨やイオン研磨を施して平滑にしなければならない。

WDSによる定量分析では、試料中の注目する元素、例えば元素A、の濃度を知るために、元素Aの濃度が判っている標準試料を用いる。標準試料と未知試料について、それぞれの元素Aの特性X線強度スペクトルを得る。ここで、標準試料と未知試料のスペクトルは同じ条件(加速電圧、プローブ電流、作動距離)で取得する。得られたX線強度の比(相対強度)に、標準試料中の元素Aの濃度を掛け合わせて、未知試料の元素Aの濃度を得る。さらに、精度の高い濃度を得るために、この数値に、試料による入射電子の散乱、および発生したX線の試料内での吸収や蛍光励起が、標準試料と未知試料で違うことを考慮した補正(ZAF補正やΦρZ補正で得られた補正係数を掛け合わせること)を行う。注目する元素が複数の場合は、それぞれの元素に対して標準試料を準備し、前述の作業を順次行う。

WDSの定量測定には、標準試料の準備と測定に手間と時間がかかる。多数の試料の全構成元素について大雑把な濃度が分かれば良いという分析には、EDSが適している。EDSによる標準試料を使わない定量分析(スタンダードレス法)では結果がすぐに得られる。WDSとEDSでは、それぞれの長所を生かす使い方をすることが望ましい。下の表にWDSとEDSの主な特徴を示す。

| WDS | EDS | |

|---|---|---|

| 測定元素 | Be~U | Be~U |

| 測定方式 | 分光結晶による 波長分光方式 |

半導体検出器による エネルギー分光方式 |

| エネルギー分解能 | 約20 eV | 約130 eV |

| 測定速度 | 遅い | 速い |

| 多元素同時測定 | 不可 | 可 |

| 検出限界 | 10~100 ppm | 1500~2000 ppm |

| 単位電流当たりのX線検出量 | 少ない | 多い |

| 試料損傷 | 多い | 少ない |

A wavelength spectroscopy method for characteristic X-rays emitted from a specimen (WDS). The method measures the wavelength spectra using a wavelength dispersive X-ray spectrometer, and then identifies the constituent elements of the specimen (qualitative analysis) from the spectral wavelength values and determines the concentrations of the identified constituent elements from the spectral intensities (quantitative analysis). WDS can analyze elements ranging from beryllium (Be) to uranium (U).

Comparing to EDS, WDS provides a high energy resolution of about 20 eV, one order of magnitude higher than EDS. Thus, adjacent spectral lines of the characteristic X-ray spectra which cannot be observed separately by EDS can be detected separately for identifying constituent elements. Owing to a high signal-to-noise ratio of the spectrum obtained by WDS, the detection limit of trace elements of WDS is two orders of magnitude higher than that of EDS. That is, WDS can detect trace elements of 100 ppm or less, enabling qualitative analysis of very trace elements (trace light elements of boron (B) to fluorine (F)). WDS provides a high quantitative accuracy, which is compatible to that of wet chemical analysis. The analysis region (volume) is as large as several 100 nm to several µm in both horizontal and depth directions because the incident electrons scatter in the specimen (same as in the case of energy dispersive X-ray spectroscopy: EDS).

Due to its high energy resolution, WDS is suitable for qualitatively analyzing specimens that contain elements whose spectral energies are close, and also for materials containing various rare earths. Especially in qualitative analysis of the rate earths, WDS has a greater advantage than EDS because the L lines of the rare-earth elements are concentrated in a close energy region. That is, EDS cannot qualitatively analyze the constituent elements in those materials, but WDS allows for qualitative analysis (separation of different spectral lines and identification of each constituent element) of them.

However, WDS has the following disadvantages: 1) Compared to EDS, the WDS spectrometer is large-sized and complex-designed. 2) Among characteristic X-rays entering the analyzing crystal, only the X-rays which satisfy Bragg’s diffraction condition are detected by the WDS spectrometer, and thus the detection efficiency of WDS is about one hundredth that of EDS. Therefore, a large probe current of several 100 nA or more is required for acquiring the spectra with a high signal-to-noise ratio. The use of such a large probe current can cause the electron-beam radiation damage to specimens that are susceptible to heat. 3) For analyzing the characteristic X-rays of different elements, the analyzing crystal and the X-ray detector must be mechanically moved along the circumference of the Rowland circle in order to independently detect the characteristic X-rays of each element. The measurements of the X-rays are executed separately for each wavelength, or multiple elements cannot be analyzed simultaneously (unlike EDS). Accordingly, WDS requires a long measurement time. 4) If the analysis region of the specimen surface has an unevenness of around 10 µm, the target analysis point is deviated from the Rowland circle. As a result, the convergence of the characteristic X-rays at the detection point becomes worse and the X-ray intensity detected decreases. To prevent this adverse phenomenon, the specimen surface must be mechanically polished or ion-beam polished to make the specimen surface even.

In quantitative analysis using WDS for a constituent element of interest, a standard specimen is required, whose concentration of this element (Element A) is known.

The first step is to acquire each spectral intensity of characteristic X-rays of Element A in the standard specimen and in an unknown specimen. Here it should be noted that, the conditions to acquire the spectra from the standard and unknown specimens are the same (accelerating voltage, probe current and working distance). The intensity ratio of the characteristic X-rays of Element A in the unknown specimen to those of the standard specimen is calculated. Then, the concentration of Element A in the unknown specimen is obtained by multiplying the concentration value of Element A in the standard specimen to the obtained intensity ratio.

The next step is to apply correction to the obtained concentration of Element A in the unknown specimen for obtaining a high accuracy concentration. That is, the high accuracy concentration of Element A is obtained by multiplying the correction factor calculated by the ZAF method or the φρZ (Phi-Rho-Z) method, where the correction takes account of the differences in 1) the scattering features of the incident electrons and 2) the absorption and fluorescence excitation effects between the standard specimen and the unknown specimen. If there are various elements of interest, standard specimens must be prepared for each element and the steps described above are repeated to obtain the concentrations of each element.

WDS quantitative analysis requires the preparation of standard specimens and takes time and effort for measurement. Thus, to obtain rough concentrations of all of the constituent elements in various specimens, EDS is suitable (WDS is not suitable). The standard-less quantitative analysis using EDS provides satisfactory results. Accordingly, the use of WDS or EDS depends on analytical purposes.

The table below lists the advantages and disadvantages of WDS and EDS.

| WDS | EDS | |

|---|---|---|

| Detectable element range | Be to U | Be to U |

| Detection method | Wavelength disperive method with analyzing crystal |

Energy disperive method with semiconductor detector |

| Energy resolution | About 20 eV | About 130 eV |

| Measurement speed | Slow | Fast |

| Simultaneous multiple-element analysis | Not possible | Possible |

| Detection limit | 10 to 100 ppm | 1500 to 2000 ppm |

| Detection X-ray volume per current | Little | Many |

| Specimen damage | Many | Little |

関連用語から探す

説明に「波長分散X線分光法」が含まれている用語