樹脂包埋

樹脂包埋

resin embedding

[目次:試料作製]

樹脂包埋は、試料の切断や割断、研磨などの加工を行う前に、試料を樹脂に埋め込む手法である。脆く壊れやすい試料(例えば、多孔質体、錠剤)や柔らかくて応力で変形しやすいソフトマテリアル(例えば、ポリマー、生物試料)を樹脂によって補強して、加工による変形を抑制できる。また、サイズの小さい金属試料や粉体試料を樹脂に埋めることで、加工に適したサイズや形状に成型できる。

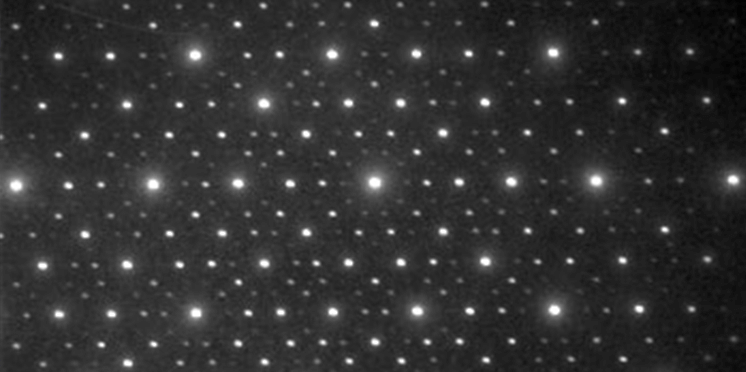

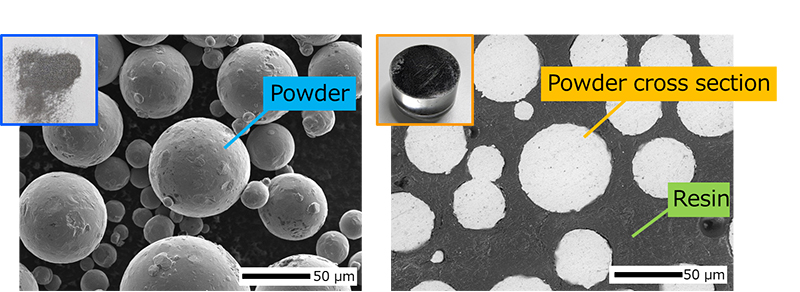

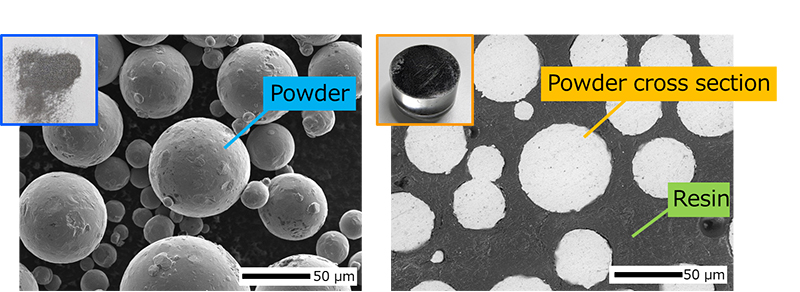

図1に、金属3Dプリンターの素材として使用されているTi合金粉末を樹脂包埋した後に切削・研磨し,粉末の断面をSEMで観察した例を示す。粉末の断面には、大きな空隙がなく、また不純物も含まれていないことから、粉末の品質が十分に高いことを確認できる。直径数十μmの粉末をそのまま切削・研磨して断面を作製することは難しいが、樹脂に包埋することで切削・研磨が可能になる。

図1 Ti合金粉末の二次電子像 (左) と樹脂包埋した後、切削・研磨した粉末の断面の反射電子像 (右)

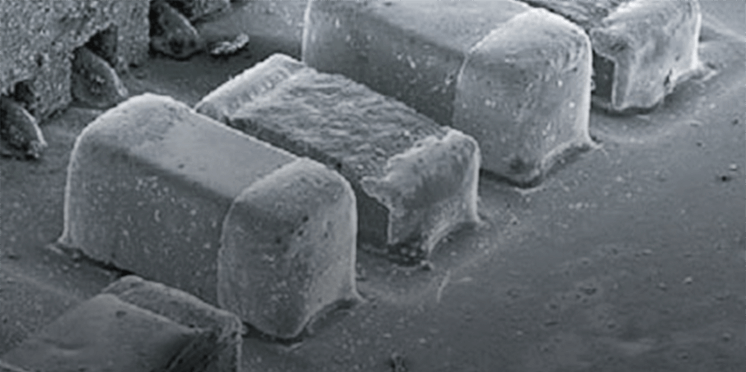

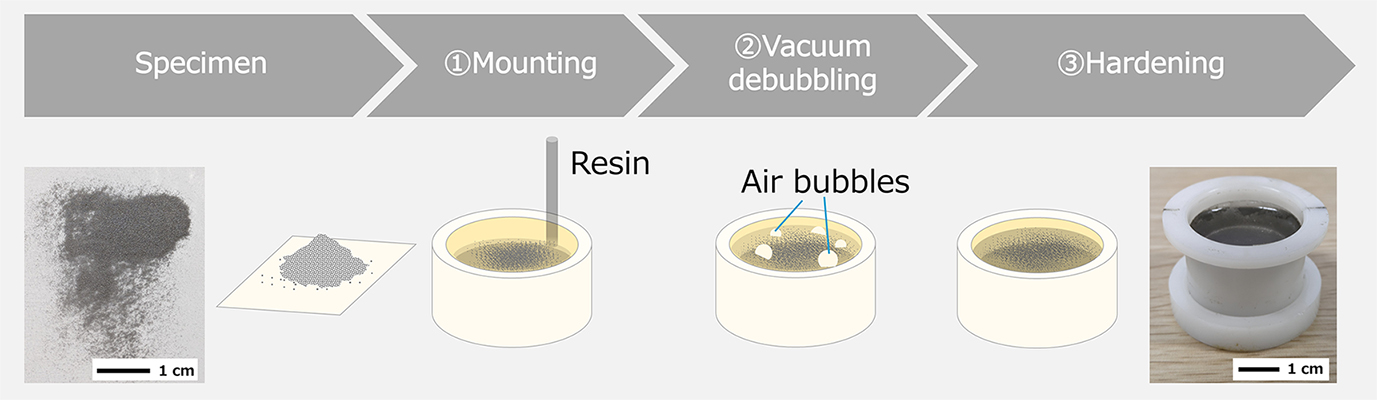

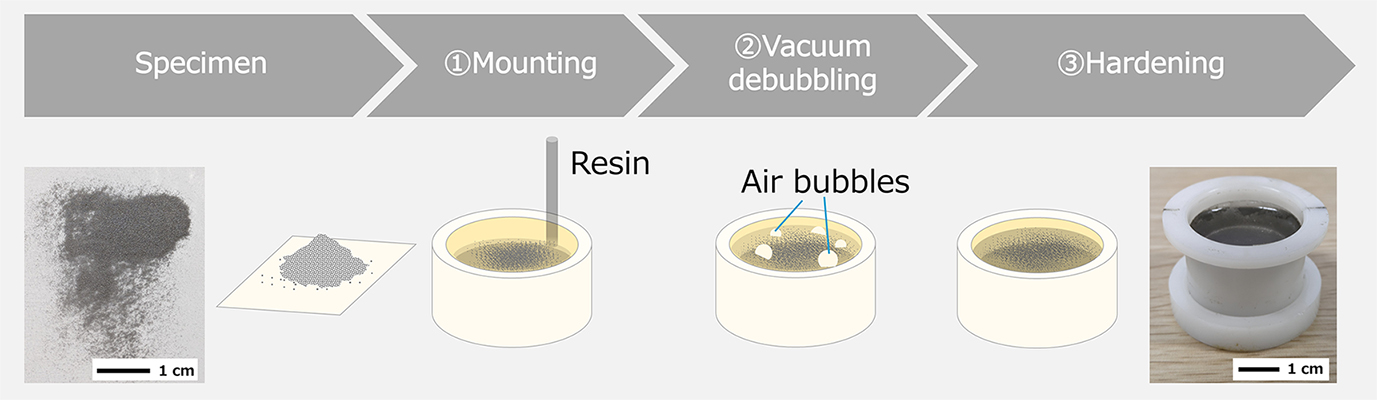

図2にTi合金粉末を冷間樹脂で包埋する手順を示す。まず粉末試料の入った容器に樹脂を静かに加え、試料全体を樹脂に埋める。その後、真空脱泡装置を用いて気泡を取り除き、試料と樹脂を密着させる。十分に脱泡した後、静置して樹脂をしっかりと硬化させる。

図2 樹脂包埋の一般的な手順

試料を樹脂に埋め脱泡し、試料と樹脂を密着させる。静置して樹脂をしっかりと硬化させる。

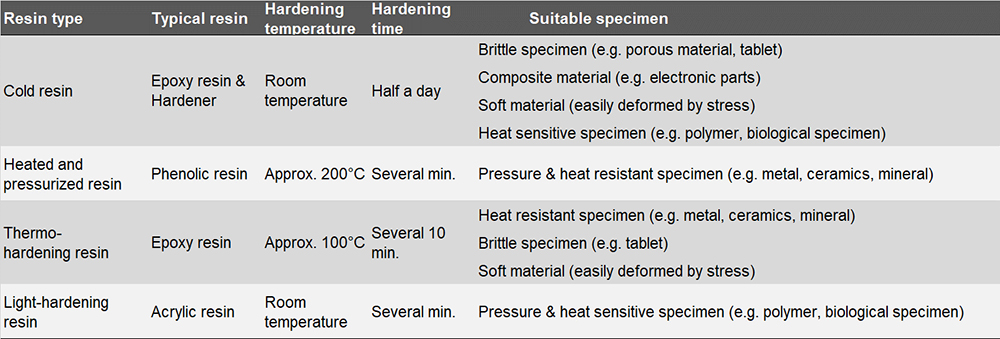

SEMで使用される包埋樹脂は、硬化方法の違いで、冷間樹脂、加熱加圧樹脂、熱硬化樹脂、光硬化樹脂の4つに分類できる(表1)。包埋樹脂は、種類によって特徴が異なるため、試料の材質や形状に応じて適切な樹脂を選択する必要がある。

表1 SEMで使用される包埋樹脂

1)冷間樹脂は、室温で包埋できる最も基本的な樹脂で、硬化に半日程度かかるが室温で静置するだけで硬化する。硬化中は反応熱のために樹脂が40℃前後に温まる。冷間樹脂はサイズの小さい金属やセラミックス、粉体試料、脆く壊れやすい試料(多孔質体、錠剤)、複合材料や電子基板、ソフトマテリアル(ポリマー、生物試料など)といったあらゆる試料に用いることができる。初めて樹脂包埋に取り組む場合には、冷間樹脂を試すのが良い。

2) 加熱加圧樹脂は、熱と圧力で変形しない試料(金属、セラミックス、鉱物)に用いられる。約200℃で数MPaの圧力を加えると数分で硬化する。硬化時間が短いので短時間で試料作製ができる。そのため多数の試料を樹脂包埋するのに適している。

3) 熱硬化樹脂は硬化時間の短さと扱える試料種類の多さのバランスが良い。冷間樹脂と加熱加圧樹脂の中間的な特徴を持ち最もよく使われる。約100℃の熱を加えると数十分で硬化する。ただし、熱で変形するプラスチック試料や生物試料は包埋できない。また、多孔質体も樹脂が穴に入り込む前に樹脂が硬化してしまうため適さない。

4) 光硬化樹脂は、可視光や紫外線の照射によって数分で硬化する。冷間樹脂と同様に室温で硬化するため熱や圧力で変形するソフトマテリアル(ポリマー、生物試料など)に用いられる。加熱加圧樹脂と同様に硬化時間が短いため、短時間で試料作製ができる。ただし、試料の形状や色により、樹脂に光が届かず、包埋できないこともある。光硬化樹脂は試料に制限があるため4種の樹脂の中で最も利用頻度が少ない。

樹脂包埋した試料をSEMで観察・分析する際には、樹脂部分の帯電や樹脂由来の元素が検出される恐れがあることに注意が必要である。

Resin embedding is a method used to embed a specimen in a resin prior to specimen processing, such as cutting, fracturing and polishing. Even brittle specimens (e.g. porous materials, tablets) and soft materials which are easily deformed by stress (e.g. polymers, biological specimens) can be reinforced by the resin to suppress deformation due to the processing. Small-sized metal specimens or powder specimens can be molded into a size or shape suitable for the processing by embedding them in a resin.

Fig. 1 shows an example of SEM images taken from Ti alloy powders used for a metal 3D printer, and from a cross section of the powders cut and polished after resin embedding. The SEM image of the cross section to the right shows no large voids and no impurities, confirming sufficiently high quality of the Ti alloy powders. It is difficult to cut and polish powders of a diameter of several 10 μm directly, but this example shows that the powders can be cut and polished by embedding the powders in the resin.

Fig. 1. Secondary electron image of Ti alloy powders (left) and Backscattered electron image of the cross section of the powders cut and polished after resin embedding (right).

Fig. 2 illustrates the embedding procedure of a powder specimen in a cold resin. The resin is gently poured to a container housing the specimen until the resin entirely embeds the specimen. Then, using a vacuum debubbling machine, air bubbles are removed to attain close contact between the specimen and resin. After sufficient removal of air bubbles, the resin containing the specimen is left still to harden the resin firmly.

Fig. 2. General procedure of resin embedding

The specimen is embedded in the resin. Air bubbles are removed to get close contact between the specimen and resin. The resin containing the specimen is left still to harden the resin firmly.

Resins used for embedding in SEM are classified into four types depending on the hardening method; cold resin, heated and pressurized resin, thermohardening resin and light curing resin (Table 1). Since each resin has different characteristics, it is needed to choose a suitable resin according to the properties or shape of the specimen.

Table 1. Resins used to embed a specimen for SEM

1) The cold resin is the most basic resin because it hardens simply by leaving it still at room temperature though it requires half a day for hardening. During hardening, the cold resin warms up to about 40 °C due to reaction heat. The cold resin is used for all types of specimens, including small-sized metals or ceramics, powder specimens, brittle specimens (g. porous materials, tablets), composite materials, electronic circuit boards, and soft materials (e.g. polymers, biological specimens). The cold resin is recommended to use when trying resin embedding for the first time.

2) The heated and pressurized resin is used for specimens which do not deform by heat or pressure (e.g. metals, ceramics, minerals). It hardens in several minutes when a pressure of several MPa is applied at about 200 °C. Owing to its short hardening time, this resin enables specimen preparation in a short time. Thus, the heated and pressurized resin is suited to resin embedding of many specimens.

3) The thermo-hardening resin offers a good balance between a short hardening time and variety of specimens that can be applied to. Thus, this resin is most widely used as it has an intermediate characteristic between those of the cold resin and the heated and pressurized resin. That is, by applying a heat of about 100 °C, this resin hardens in several 10 minutes (much shorter than in the cold resin). However, plastic specimens and biological specimens cannot be embedded by this resin because they are deformed by heat. Porous materials are also unsuitable because this resin hardens before it reaches to the holes of the materials.

4) The light-hardening resin hardens in several minutes by irradiation of visible or ultraviolet light onto the resin. It hardens at room temperature like the cold resin. Thus, this resin is used for soft materials (e.g. polymers, biological specimens) which are deformed by heat or pressure. Like in the heated and pressurized resin, as the hardening time is short, specimens are prepared in a short time.

However, the specimens with a shape or color which does not allow light to reach this resin, are not possible to embed. The light-hardening resin is least frequently used among the four types of resins 1) to 4) due to the limited variety of applicable specimens.

When the resin-embedded specimens are observed and analyzed by SEM, attention should be paid to that the resin part can be charged and the elements originating from the resin may be detected.

関連用語から探す

説明に「樹脂包埋」が含まれている用語